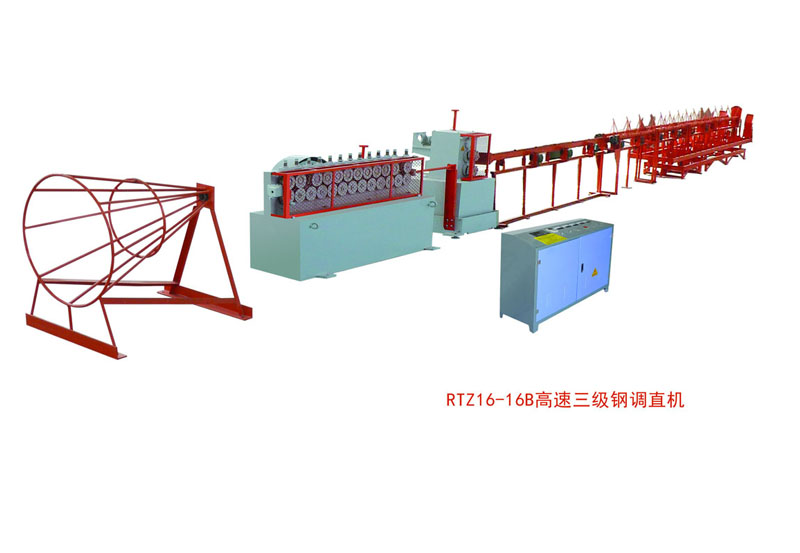

RTZ16-16B type cold rolled ribbed bar equipment, hot rolled ribbed steel bar straightening and cutting machine, suitable for cold rolled ribbed steel bar straightening and cutting line, hot rolled ribbed steel bars (three steel) straightening and cut, construction, concrete, mesh processing length straight wire of the ideal equipment.

- features: straightening system: multi wheel group by our factory for the production of the machine structure, consists of 2 groups of horizontal and vertical multi wheel straightening, straightening system with position memory testing, replacing steel bars of different diameters, straightening wheel will automatically adjust downward or upward, reaching for steel bars fast straightening (patent technology), shorten the time of steel bar straightening, the whole process can be completed automatically, multi wheel synchronous traction steel wheel and steel pressure decreases, and the traction force is small, energy consumption, reduce the loss of steel.

Features two: cutting system: imported servo motor, to ensure cutting accuracy, support high speed, frequent start cutting, so that reliability and durability improved greatly.

Control system: the use of advanced PLC program control, color touch screen display, key input, to reduce the poor environment caused by touch screen damage, the key parts of imported brand-name products. It has the function of fault identification and alarm.

Thirty sets of preset length, high efficiency, 500 millimeters length, high precision, high efficiency and low loss.

Equipped with wire drawing machine, it can form an efficient equipment for continuous rolling + on-line straightening, which can automatically adjust the speed of wire drawing machine.

The original intermittent flying shear, cut off, once the motor, only 0.15 seconds work, mechanical and electrical loss of small, long service life, high cutting accuracy, to avoid the traditional straightening machine continuous cutting, poor working reliability and other defects.

Using the principle of bending stress elimination, straightening and straightening, the wire has no scratch and little strength loss.

The control part is separated from the main computer to improve the reliability of the electronic control system.

• the blanking frame adopts 360 degree rotation design without clamping strips, so as to avoid the defects of regular adjustment and unsmooth blanking.

Note: according to the user's requirements: increase the automatic stop without material, two times material, finished products, conveyor belt and other functions.

The company introduced a new straightening machine, straightening speed of more than 200m/min, and straightening effect is good, do not flip, not distorted. Interested parties may consult our company.

|

Name

|

Company

|

Technical parameter

|

|

Model

|

|

LTZ12-12A

|

LTZ12-12B

|

LRTZ12-12A

|

LRTZ12-12B

|

RTZ12-12A

|

RTZ16-16B

|

|

Types of straightening reinforcement

|

|

Cold rolled and hot rolled coil

|

Cold rolled and hot rolled coil

|

Cold rolling and hot rolling plate

|

Cold rolling and hot rolling plate

|

Hot rolled plate

|

Hot rolled plate

|

|

Straightening diameter

|

mm

|

Φ4-10/12

|

Φ4-10/12

|

Φ4-12

|

Φ4-12

|

Φ5-12

|

Φ6-16

|

|

Straightening speed

|

m/min

|

50

|

80

|

80

|

180

|

180(200)

|

180(200)

|

|

Predetermined length

|

m

|

0.5--99

|

0.8--99

|

1--99

|

1--99

|

1--99

|

1--99

|

|

Cutting error

|

mm

|

±7(±2)

|

±5(±2)

|

±5(±2)

|

±2

|

±2

|

±2

|

|

Length of chute

|

m

|

6

|

8

|

8

|

8--12

|

8--12

|

8--12

|

|

Length of material rack

|

m

|

1--12m( More than 9 meters is optional)

|

|

control mode

|

|

A set of controls

|

Two sets of NC cycle

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

|

Host power

|

Kw

|

5.5/7.5

|

15

|

15

|

37

|

37

|

55

|

|

Cutoff power

|

Kw

|

2.2

|

4

|

4.5

|

5.5

|

5.5

|

7.5

|

|

Working area (including discharge)

|

Length * width * height

|

12×1.5×2

|

15×2×2

|

15×2×2

|

30×2×2

|

30×2×2

|

40×2×2

|

|

Weight (approx.)

|

Kg

|

1500

|

1800

|

8200

|

5200

|

5000

|

7200

|

|

Number of tow wheels

|

only

|

6

|

6

|

6

|

10

|

10

|

10

|

|

Straightening method

|

|

rotate

|

rotate

|

Vertical and horizontal and rotate

|

Vertical + water product

|

vertical

|

vertical

|

|

Speed regulation method

|

|

Single speed

|

Two segment velocity

|

Two segment velocity

|

frequency conversion

|

frequency conversion

|

frequency conversion

|

|

Shear control mode

|

|

CNC machine

|

CNC machine

|

servo control

|

servo control

|

servo control

|

servo control

|

|

Shear length measuring method

|

|

|

|

|

Rotary coding

|

Rotary coding

|

Rotary coding

|

|

Unloading rack form

|

|

single

|

single

|

double

|

double

|

double

|

double

|

|

Automatic reinforcing bar leveling device

|

|

|

|

|

yes

|

yes

|

yes

|

|

Φ6Reinforcement yield

|

Kg

|

666kg/h

|

1000kg/h

|

1000kg/h

|

2398kg/h

|

2398kg/h

|

2500kg/h

|

|

Φ8Reinforcement yield

|

Kg

|

1180kg/h

|

1900kg/h

|

1900kg/h

|

4200kg/h

|

4200kg/h

|

4200kg/h

|

|

Φ10Reinforcement yield

|

Kg

|

1840kg/h

|

2950kg/h

|

2950kg/h

|

6000kg/h

|

6000kg/h

|

6000kg/h

|

|

Φ12Reinforcement yield

|

Kg

|

|

|

|

7000kg/h

|

7000kg/h

|

7000kg/h

|

|

Φ14Reinforcement yield

|

Kg

|

|

|

|

|

|

8000kg/h

|

|

Φ16 Reinforcement yield

|

Kg

|

|

|

|

|

|

9000kg/h

|

|

Operator

|

People / Unit

|

1

|

1

|

1

|

2

|

2

|

2

|